The smart Trick of Mfg That Nobody is Discussings

Wiki Article

The smart Trick of Die Casting That Nobody is Discussing

Table of ContentsManufacturing for BeginnersSome Of Lean ProductionAll about Additive ManufacturingSee This Report about Die CastingThe 10-Second Trick For Die CastingThe 6-Minute Rule for Die Casting

The message on this page is an example from our complete White Paper 'Injection Moulding for Customers' - * Sample text * - for complete overview click the download button above! Introduction This guide is meant for individuals that are wanting to source plastic mouldings. It provides a much needed insight right into all that is entailed with developing plastic components, from the mould device required to the moulding process itself.If you wish to discover further, the guide covers kinds of mould tools, as well as special finishing processes such as colours & plating. Words that are highlighted can be discovered in the glossary in the appendix ... Component I: Moulding: The Essentials The Advantages of Injection Moulding Plastic shot moulding is a very specific process that uses numerous advantages over various other plastic handling approaches.

Precision is excellent for extremely detailed components. Compared to other strategies, moulding enables you to include more functions at very small resistances. Have an appearance at the photo to the. You can hold this moulding in the palm of your hand and also it has employers, ribs, metal inserts, side cores and also openings, made with a moving closed off feature in the mould device.

Not known Incorrect Statements About Manufacturing

Getting The Mfg To Work

from material feed & melting; material injection; shot time and ejection and also the re-closing of the mould tool ready for all set next cycle. Draft angles - The walls of a moulded part need to be a little tapered in the direction in which the component is expelled from the mould device, to permit the part to be expelled quickly.Ejector stroke - The pressing out of ejector pins to eject the moulded part from the mould tool. Ejector stroke speed, size as well as timing needs to be carefully managed to avoid damage to the ejectors and also mould tool, yet at the exact same time make the moulding cycle as short as feasible.

The Best Strategy To Use For Plastic Manufacturing

Ribs - When a plastic component has slim walls, ribs are contributed to the layout to make the thin walls stronger Side cores - Side activity which produces a function on a moulded part, at an opposing angle to the regular opening direction of the mould tool. lean production. The side core needs to be able to withdraw as the plastic component can not be ejected otherwise.

Walls - The sides of a moulded component The text on this page is an example from our complete White Paper 'Injection Moulding for Buyers'.

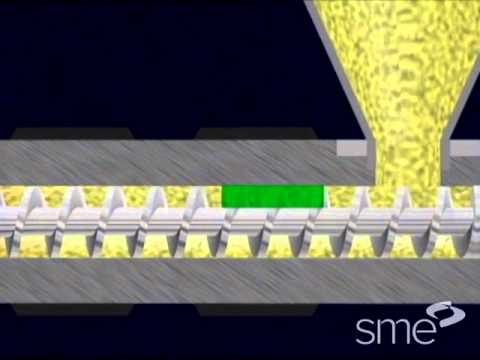

Injection moulding is commonly utilized for manufacturing a selection of components, from the tiniest components to whole body panels of vehicles. Developments in 3D printing modern technology, making use of photopolymers that do not thaw throughout the injection moulding of some lower-temperature thermoplastics, can be utilized for some easy shot moulds. Injection moulding makes use of a special-purpose maker that has 3 components: the shot system, the mould and also the clamp.

The Manufacturing Ideas

Process characteristics [modify] Shot moulding utilizes a ram or screw-type plunger to compel liquified plastic or rubber product right into a mould tooth cavity; this solidifies right into a shape that hon hai precision has adapted to the shape of the mould. It is most generally made use of to refine both polycarbonate as well as thermosetting polymers, with the volume utilized of the previous being significantly higher.: 13 Thermoplastics are common because of features that make them very ideal for injection moulding, such as ease of recycling, adaptability for a large range of applications,: 89 and ability to soften and also flow on home heating.In numerous cavity moulds, each cavity can be identical and create the same components or can be special and create several various geometries during a single cycle.

The screw delivers the raw product onward, blends and also why not check here homogenises the thermal as well as thick distributions of the polymer, and minimizes the needed home heating time by mechanically shearing the product and also including a considerable quantity of frictional home heating to the polymer. The product feeds ahead with a check shutoff as well as accumulates at the front of the screw into a volume called a shot. When enough material has actually collected, the product is required at high stress and also velocity into the part forming tooth cavity. The precise amount of shrinking is a feature of the material being made use of, and can be fairly foreseeable. To stop spikes in pressure, review the procedure typically uses a transfer position corresponding to a 9598% full cavity where the screw shifts from a constant velocity to a constant stress control.

Fascination About Manufacturing

The packaging stress is applied up until the gateway (cavity entry) solidifies. Due to its small size, the entrance is typically the very first place to solidify via its whole thickness.: 16 Once the gate solidifies, no even more product can enter the tooth cavity; as necessary, the screw reciprocates and also gets product for the next cycle while the material within the mould cools so that it can be ejected and be dimensionally steady.Report this wiki page